We have Liquid and powder PVC heat stabilizers for both flexible and rigid PVC applications.

Changsheng Material’s PVC Stabilizer:

Our main products include Methyl Tin Mercaptide Stabilizer, Ca/Zn Stabilizer, Antimony Mercaptide Stabilizer, Phenyl Diisooctyl Phosphite(PDOP), ESBO, and other auxiliary processing additives like Optical Brightening, PVC Deodorant, UV Absorbers, etc.

According to the production characteristics of different PVC soft and rigid products, we recommend different cost-effective heat stabilizers suitable for your machines and production formulas.

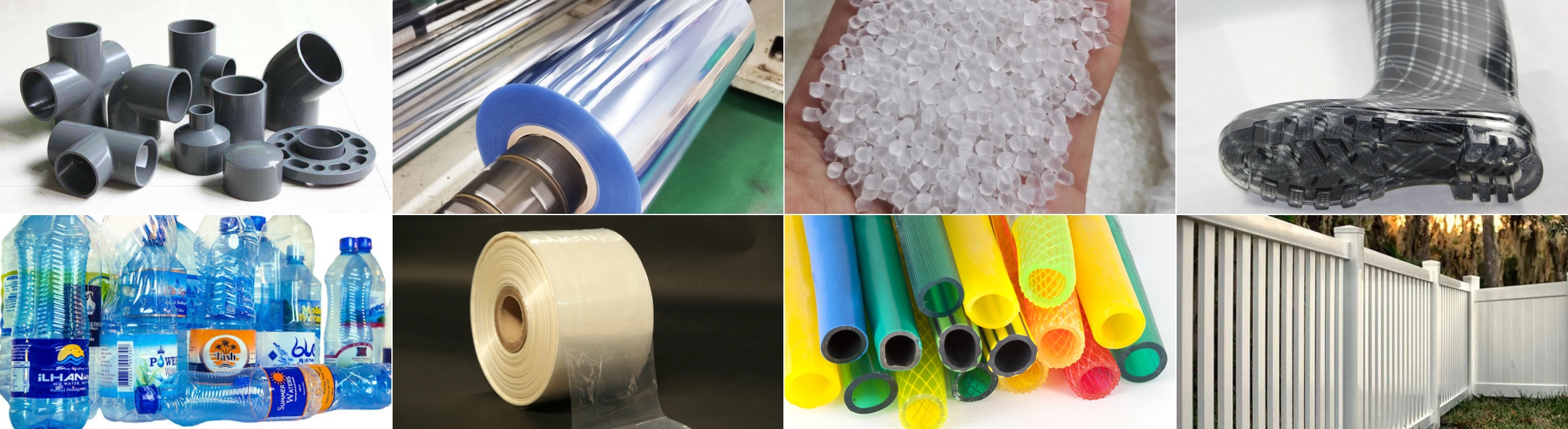

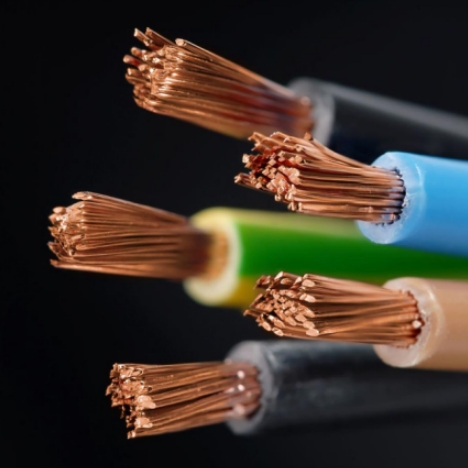

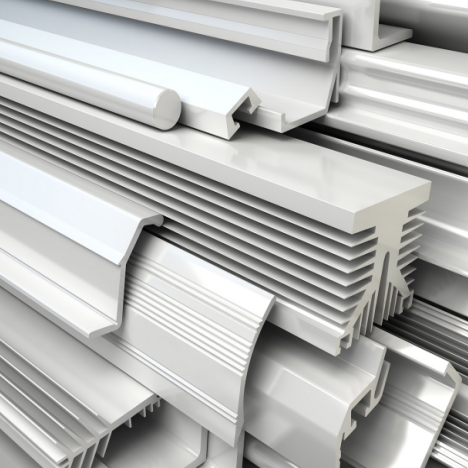

We have much service experience and customer base in the fields of PVC transparent products such as PVC shrink film packaging, PVC rigid sheets, PVC transparent compounds,granules, PVC shoes, PVC pipes and fittings.

If you have any questions in this PVC application, please feel free to contact our team.

The PVC stabilizer function in the PVC production and processing:

When PVC is processed at high temperature, HCL is easily released to form an unstable polyene structure. At the same time, HCL has a self-catalytic effect, which will further degrade PVC. PVC heat stabilizer can capture the self-catalytic HCL released by PVC resin, or react with the unstable polyene structure produced by PVC resin to prevent or reduce the decomposition of PVC resin. During the effective use period of the product, it maintains sufficient thermal stability and slows down the degradation caused by heat, light, and prolongs its service life.

Different types PVC stabilizers are suitable for different PVC industry.

Lead based PVC stabilizers are mainly used in hard products. Lead salt stabilizers have the characteristics of good heat stabilizers, excellent electrical properties, and low price. However, they are toxic and can only produce opaque products.

Ba-zn PVC stabilizers are a type of heat stabilizer with better performance. They are widely used in PVC films. Usually barium cadmium zinc and organic phosphites and antioxidants are used together.

Ca-Zn stabilizers can be used as non-toxic stabilizers and are used in food packaging, medical devices, and pharmaceutical packaging, but their stability is relatively low. When the amount of calcium stabilizers is large, the transparency is poor and it is easy to spray frost. Calcium zinc composite stabilizers are now the choice of many companies.

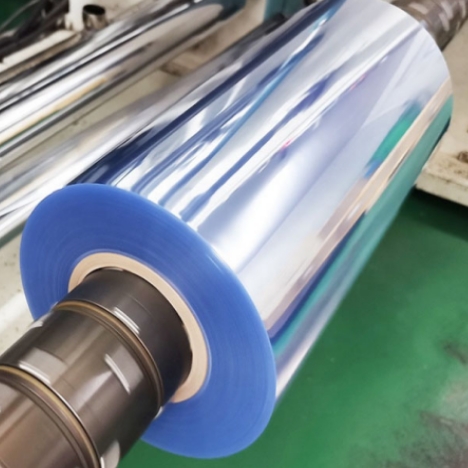

Organic tin heat stabilizers have better performance for PVC hard products and transparent products, especially in PVC packaging films, packaging sheets, transparent pipes and other fields.The more popular in the world now are methyl tin mercaptide PVC stabilizers and methyl tin composite stabilizers.

Epoxy stabilizers are usually used as auxiliary stabilizers. This type of stabilizer can improve the light and heat stability when used with barium, cadmium, calcium, zinc, and tin stabilizers. Its disadvantage is that it is easy to seep out. Other auxiliary stabilizers include polyols, organic phosphites, etc.

The Most Cost-effective PVC Stabilizer For Your PVC Products

PVC Stabilizer Delivery Case