What is PVC stabilizer?

PVC heat stabilizers are mainly used for PVC and other chlorine-containing polymers. It has been found that PVC plastic can only be processed at a temperature above 160 °C, and it begins to decompose at 120~130 °C, releasing HCl gas thermally. If the production of HCl is not inhibited, the decomposition will be further intensified.

The product used for polyvinyl chloride to improve polymer stability and inhibit the decomposition of polyvinyl chloride is PVC stabilizer.

PVC stabilizers mainly include lead salts, fatty acid metals, organic tin, etc. composite heat stabilizers.

Changsheng’s Methyl Tin Mercaptide, Antimony Stabilizers,Ca-Zn Stabilizers,Lead Stabilizer, cover almost all PVC industrial fields.

Tin PVC Sabilizer And Antimony PVC Stabilizer

Our main product is the Methyl Tin Mercaptide stabilizer CS-181. Tin content is 19.2%,can used for PVC transpartents rigid product.

The lowest-cost stabilizer is mainly used for non-transparent hoses and PVC conveyor belts, etc. Low price and low dosage.

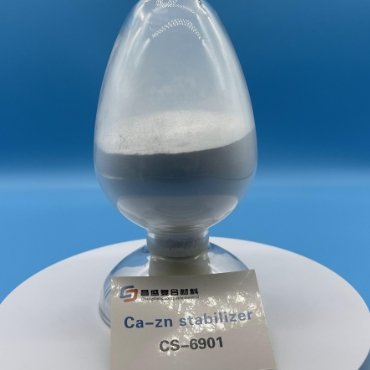

Calcium-Zinc PVC Stabilizer Series

Calcium-Zinc Stabilizers are composed of calcium salt, zinc salt, lubricant, antioxidant, and so on. And can be customized according to PVC products.

Ca-zn PVC heat stabilizers have good heat stability, light stability, transparency, and tinting ability.

In PVC products producing, its processing performance is good, and the thermal stability is equivalent to the lead salt stabilizer, which is a good non-toxic stabilizer.

PVC Lead Stabilizer And Auxiliary PVC Stabilizer

- PVC One Pack Stabilize,This is a composite type of PVC lead heat stabilizer that can be directly used and has excellent stability and lubricity.

- Organic auxiliary heat stabilizer, which has little heat stabilization effect on its own,good antioxygenic property and is a pure organic compound that can significantly improve heat stability when combined with other metal stabilizers.

Changsheng's PVC Stabilizer Feature

Our PVC heat stabilizer products have been approved by the reach,FDA.Specific model is compatible with food, medical packaging and applications.All PVC stabilizers model widely used in many differrnt PVC indusrtry .

Our PVC heat stabilizer has good dispersibility, compatibility, processing fluidity, and wide adaptability during processing with PVC resin. Always have good effects.

Whether methyl tin mercaptide stabilizer or calcium-zinc stabilizer, all can be used in the PVC industry with high transparency, transparency PVC application is our specialty.

Our PVC heat stabilizer can still maintain the excellent characteristics of the product under high-temperature conditions and is not easy to decompose.Wide range of uses.

PVC Tin Stabilizer Methyl Tin Mercaptide 181

Changsheng has been focusing on the research and development of methyl tin stabilizers for 20 years and is one of the earliest factories in China to introduce methyl tin production lines. Especially in the PVC hose plastics and PVC film flexible plastics application field, we have a lot of experience in service and production.

PVC Ca-Zn Stabilizer

Changsheng’s Calcium-Zinc Stabilizers also has many years of development history, Its manufacturing process is relatively simple, absolutely non-toxic, can be used in the medical field, and can replace methyl tin stabilizer in some PVC industry.

We have a capacity of ten thousand tons and overcome the technology of transparent products.

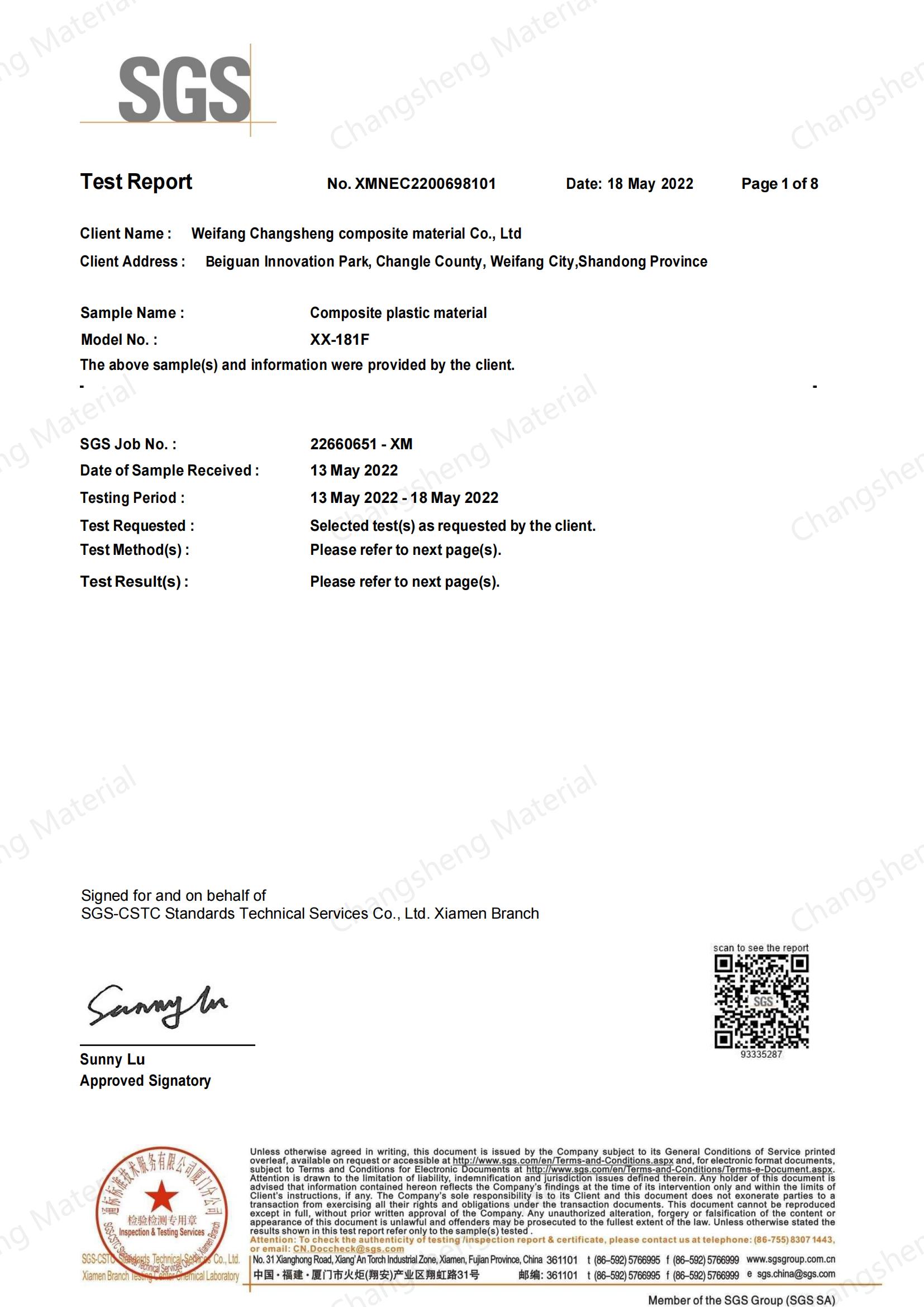

PVC Stabilizer Quality Contral

- Raw material quality control.

- Advanced production technology and equipment.

- Sampling and testing many times before leaving the factory.

- Pay attention to packaging, and container inspection.

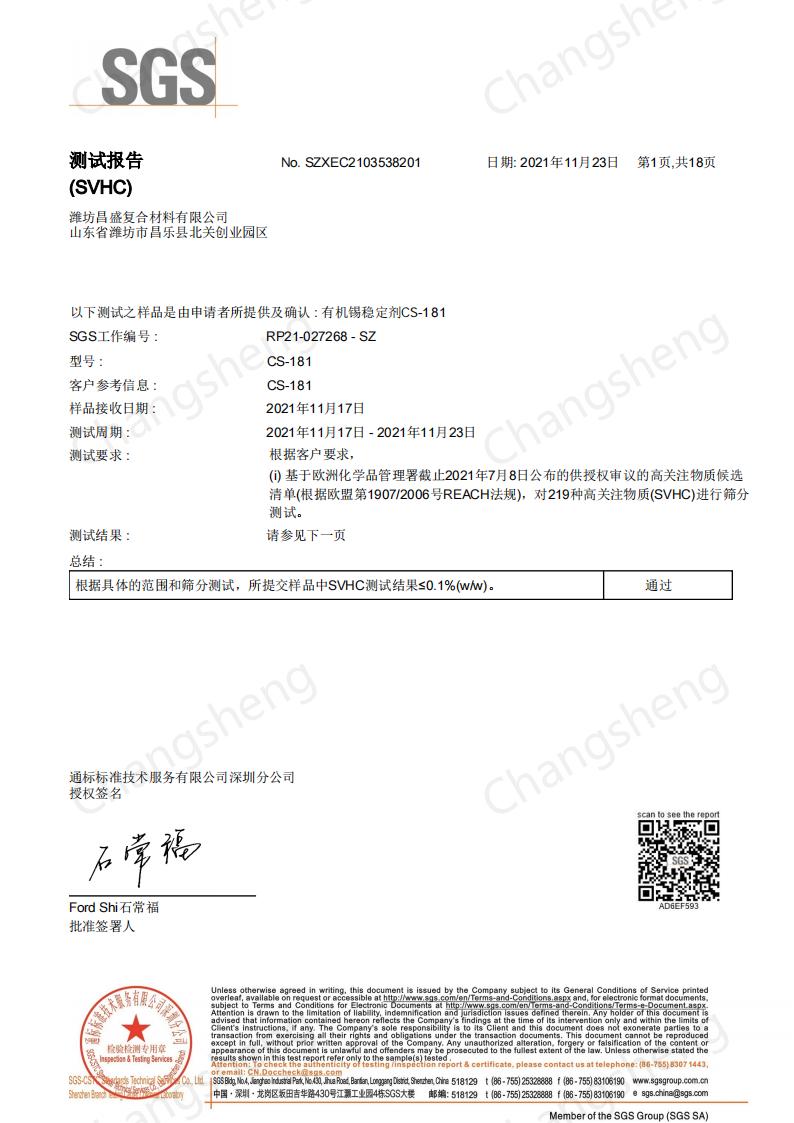

- SGS test report.

Changsheng's PVC Stabilizers Production

With the continuous expansion of market demand, Changsheng Material will continue to improve production scale, increase supply chain value, and continue to provide environmentally friendly, efficient, and economical PVC stabilizer products.

Contact us now!

The Best Selling PVC Stabilizers

- 19% tin content is guaranteed

- High efficient heat stability and excellent initial color stability

- Good resistance to scaling

- Good compatibility and processing liquidity

- It is equivalent to AMERICAN TM-181-FS

- Environmental protection non-toxic

- Low cost

- Wide range of applications

- Good dispersity, compatibility, processing liquidity

- Good thermal stability

Changsheng's PVC Stabilizer Application

PVC heat stabilizer can prevent the discoloration and heat decomposition of PVC granules during processing and can maintain sufficient heat stability, slow down the degradation caused by heat, light, and oxygen, and prolong the service life of the second processed PVC products.

Include PVC shrinkable packaging film, printing film, calendering film, kindling film, twisting film, etc.

PVC pipe,Water pipes, electrical pipes, pipe fittings, electrical fittings, transparent pipe fittings, CPVC, UPVC.

We have served more than 1000 PVC hose manufacturers, we have rich experience in this area, you can contact us for the best production advice.

Some Details About Our PVC stabilizers

- SGS Test Report

- R&D Team

Related Product

Changsheng Material—Leading PVC Stabilizer Manufacturer in China

Changsheng has 20 years of experience in manufacturing methyl tin mercaptide stabilizer,Calcium zinc stabilizer,Antimony PVC heat stabilizer,etc.

19% Tin Content Methyl Tin Mercaptide, the most common organotin stabilizer is widely used in the processing industry of polyvinyl chloride (PVC) resin, which is suitable for various PVC processing processes such as extrusion, calendering, blow moulding and injection moulding, etc.

Methyltin Stabilizer 181 is our best-selling model and one of the most widely used and most stable stabilizers. Of course, all products come from the needs of consumers. You can contact us and tell us the industry you serve, and we will give you the best recommendation.

CS-181 is a conventional stabilizer with 19% tin content, and with the high price, it is the best stabilizer. CST-181 is a special compound stabilizer for the PVC shrink film industry. It combines the advantages of methyl tin stabilizer and antimony mercaptan stabilizer, with low cost, low dosage, and good effect.

We have been developing calcium and zinc stabilizers for many years. After feedback from the market and experiments of the R&D team, especially in the field of transparent soft products, our calcium and zinc stabilizers have a very good effect. For ordinary calcium zinc stabilizer 69 series, you can choose with confidence, after all, this kind of stabilizer has a simple process and is very common.

Yes, we have a strong research and development team. So OEM and ODM services are provided to our customers. If you have special requirements, please do not hesitate to contact us at any time.

Yes, sure, we are honored to offer you samples, If you need, we can provide free samples for you to test, you only need to pay the freight.

If you want to save costs, you can purchase directly, we will issue quality assurance, and SGS certification report, our products have been used in the market for a long time, plus we have rich experience in the industry, we guarantee that the qualified rate of products is 99%. And we’re gonna give you the best advice.