What is PVC Antimony Mercaptide Heat Stabilizer?

Antimony mercaptide stabilizer, also known as organic antimony stabilizer, is a new type of PVC heat stabilizer, with good initial coloring and processing stability, its thermal stability is comparable to the tin stabilizer and better than calcium-zinc stabilizer, is non-toxic and environmentally friendly, its price is much cheaper than methyl tin stabilizer.

Changsheng Material has been developing and producing antimony stabilizers for many years, and now the technology is mature and the PVC Antimony stabilizer is reliable, which has been applied to many PVC industries to help customers save cost.

Three Different Types of Antimony Mercaptide Stabilizers

The grade of Antimony Mercaptide stabilizers is mainly differentiated by the antimony content, meanwhile stability varies, contact us for the best recommendation.

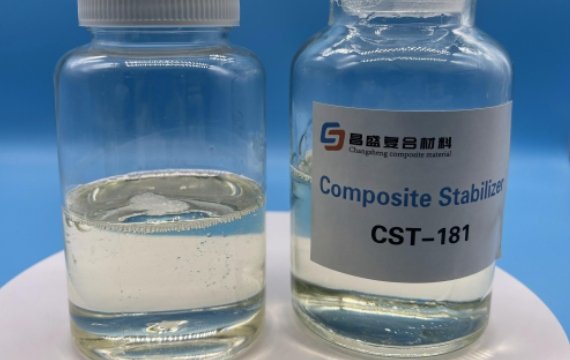

Composite Tin/Antimony Stabilizer for PVC Film CST-181

PVC Heat Stabilizer CST-181 was developed specifically for PVC films and is significantly less costly than Methyl Tin Stabilizer CS-181.

Antimony Mercaptide Stabilizer Feature

Antimony stabilizers can achieve the same stability as the tin stabilizer, but the price is only half of the tin stabilizer, it can completely replace methyltin in many PVC industries.

Changsheng’s PVC Antimony stabilizer has a very low melting point, good hue retention, good compatibility, and good synergy with calcium stearate, epoxide synergists, phosphites, etc.

Organic antimony stabilizer is non-toxic, low dosage, low price, and have good processing performance. It can be used in hard, semi-hard, and soft PVC transparent products.

Antimony Mercaptide Stabilizer has excellent thermal stability, and it is better than calcium-zinc stabilizer in soft PVC products and better than lead stabilizer in rigid PVC products.

About Antimony Mercaptide Stabilizer

Antimony stabilizer has a stabilization effect equivalent to organic tin stabilizer,and also has good heat resistance and weather resistance, so very many PVC industries began to use this PVC stabilizer.

In the use of Antimony Mercaptide Stabilizer, it has a good synergistic effect with calcium stearate, organic tin stabilizer, epoxy compounds, phosphite, and many other additives. But it must not be used with lead, cadmium, and other metal soap heat stabilizers to prevent the production of black sulfide.

At the same time, it should be stored in avoiding light and protected from water to prevent decomposition, discoloration, and precipitation.

Antimony Mercaptide Stabilizer's Supply

Changsheng’s Antimony Mercaptide Stabilizer also has many years of development history, we have rich experience in the PVC stabilizer market, and antimony stabilizer warehouse storage is around 300tons, which can meet fast delivery.

Meanwhile, the antimony stabilizer is non-hazardous and needs to be protected from sunlight and dryness. It can transport according to the standard of non-dangerous goods.

PVC Stabilizer High-quality Contral

- Quality control of raw materials

- Product sampling and testing

- Support institutions to test and provide certification

- Professional R&D team and after-sales team

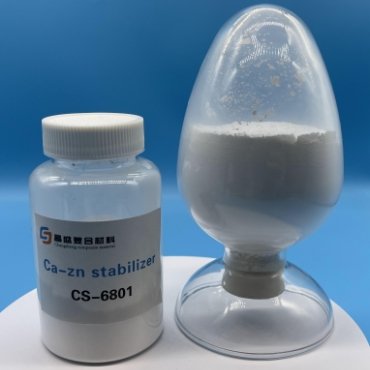

The Best Selling PVC Heat Stabilizers In Changsheng

- The best heat stability of PVC stabilizer

- Non-toxic and environmentally friendly

- Suitable for most industries in PVC

- More resistant to sunlight than antimony stabilizers

- PVC film special

- Highly efficient thermal stability and good initial color stability

- Good compatibility and process flow

- Lower cost than methyl tin stabilizer

Some Antimony Mercaptide Applications

Related Product

Antimony Mercaptide Series PVC Heat Stabilizer

Changsheng, 20 years of PVC stabilizer experience manufacturer.

Yes, we are factory. Antimony Mercaptide PVC heat stabilizer is produced in the range of 5,000 tons per year.

The stability is comparable, but one disadvantage of antimony stabilizer is that it is afraid of exposure to sunlight, while methyl tin stabilizer has better light stability in this respect.

The best-selling model CST-181, which we have specially developed for PVC film, is further optimized for formulation on the basis of antimony and methyl tin compound, which is not only effective but also saves customers’ cost greatly. It is very popular in the international market.

The other three models CST-A, CST-B, CST-D, the difference is the difference of antimony content, the main difference is the difference of stability, respectively, used in PVC film, sheet, conveyor belt, cable and wire and other fields.

Yes, antimony mercaptide heat stabilizers are recognized by several country markets and have been widely promoted in China, while meeting the standards required for food packaging.

We can also provide any certification you need.