Methyl Tin Stabilizer Brief Description:

Methyl tin stabilizer is one of the three kinds of organic tin and one of the most widely used PVC heat stabilizers, it is a viscous transparent liquid, and its stability, transparency, compatibility, and weather resistance are better than other organic tin.

Methyl tin stabilizer is suitable for all kinds of soft and hard PVC products processing, such as extrusion, calendering, injection molding and blow molding, etc.

At present, methyltin has become an important stabilizer for PVC films, sheets, granules, pipes and building materials, and is also approved for use in food packaging, medical packaging and other fields because its non-toxic and environmentally friendly.

Changsheng Material is a professional manufacturer of methyl tin stabilizers,through 20 years of development, the annual output of methyl tin stabilizers is now over 10,000 tons, which occupies an important market in China and sold to all over the world.

Methyl Tin Stabilizer Data Sheet:

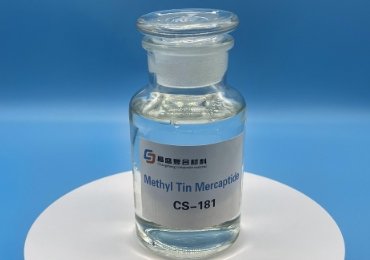

Item NO.:CS-181

CAS:57583-35-4

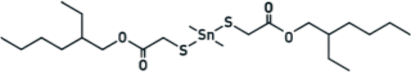

Structural Formula:C22H44O4S2Sn

| Item | Specifications |

| Appearance | Clear transparent liquid |

| Colour (Pt-Co value) | ≤50 |

| Tin Content % | 19±0.5 |

| Specific gravity (25℃, g/cm3) | 1.16±0.03 |

| Viscosity (25℃, mPa·S) | 30-90 |

| Monomethyl tin content (%) | 23.0 |

| Trimethyl tin content (%) | <0.1 |

Other name:

Methyl tin mercaptide PVC Heat Stabilizer

Methyl tin isooctyl mercaptoacetate stabilizers

Methyl tin Heat Stabilizer;

Organotin Heat Stabilizer;

Tin Stabilizer

Mercaptan Methyl Tin

Relationship Between Methyl Tin Stabilizers and Organic Tin Stabilizers:

Methyl tin stabilizer is a kind of organic tin stabilizer. Organic tin stabilizers with its excellent thermal stability, good light stability and mutual solubility and become the most important stabilizer for PVC products, and methyl tin mercaptide is the organic tin heat stabilizer in the best.

Why Choose Methyl Tin Mercaptide:

- Prevents oxidation and aging of products.

- Excellent thermal stability than other PVC stabilizers.

- Excellent transparency than other PVC stabilizers.

- Eco-friendly and non-toxic.

- Excellent liquidity and compatibility.

Application Of Methyl Tin Stabilizer:

- PVC film ( Shrinkable film, Printing film, Calendered film, Twisting film, Packing film, etc.)

- PVC sheet (Clear flexible and rigid sheet, Christmas sheet, Advertisement sheet, Compound sheet, etc.)

- PVC building and construction materials (Hose, Water pipe and Pipe Fittings, Chemical Pipes, construction materials, profile, etc.)

- PVC granules(Various soft and hard PVC granules.)

- PVC medical packing, Food packaging materials, Daily-used appliances, and others.

Packaging, Transportation and Storage of Methyltin Stabilizer:

Packed into the plastic drum, 220kg/drum, packed into IBC tank, 1100kg/IBC tank or 1200kg/IBC tank, or other customized packages.

The product is non-flammable, non-toxic, and non-explosive. Please keep it in a cool and dry place with the cover facing up to prevent water.

.jpg)

Philosophy of Methyl Tin Mercaptide Stabilizer:

PVC resin in the process of molding or long-term exposure of products in the process of use, under the action of high temperature or light can gradually decompose, and finally lead to the aging of all resin, this phenomenon is called the degradation of PVC, the main factors causing the degradation of PVC are heat, light, oxidation degradation.

1. Absorption of hydrogen chloride

HCI is released during the degradation of PVC and has a catalytic effect on its degradation, so timely absorption of HCI generated by degradation is beneficial to the stability of PVC. Methyl tin mercaptide can form feint salt with HCI and has the effect of absorbing HCI.

2. Elimination of initiation sites

Methyl tin mercaptide through its special coordination chemistry readily undergoes substitution reactions to eliminate the unstable B-chlorine atom.

3. Addition to polyene sequences

Methyl tin mercaptide can react with the double bond on the PVC chain, thus shortening the length of the polyene sequence.

4. Prevents auto-oxidation

Methyl tin mercaptides acts as an auxiliary antioxidant by decomposing hydroperoxides and thus preventing auto-oxidation.

5. Destruction of carbon-positive ion salts

The main reason for the darkening of PVC after heat degradation is the formation of carbon-positive ion salt, Methyltin stabilizer can disrupt the structure of the carbon-positive ion salt by absorbing HCI, resulting in a lighter color.